Pentangle Fabrications

Dedicated fabrication and welding services since 2011

Fabrication

We offer a full fabrication and welding service backed up by decades of hands on experience.

Pentangle manufactures and supplies a range of regular production fabrications as well as many one-off fabrications, varying from small brackets to large, machined assemblies. We pride ourselves on our ability to turn our hand to most things that come through the door!

We accept all major drawing formats in either 2D or 3D, including DXF, DWG, IGES, STEP etc and are able to produce concept and manufacturing layouts and drawings on either 2D CAD packages or 3D parametric software.

We also offer a large range of finishes, which includes machining, shot-blasting, powder coating, chemical blacking and passivating, to name but a few.

Welding Services: Sub-Contract

Pentangle Fabrications offers sub-contract robotic welding services, utilising our in-house, twin station, end changer cell, based in Grantham, Lincolnshire.

We can provide in-house design (using parametric 3D design software) and manufacture any jigs and fixtures required to hold parts.

Weld trials can also be carried out at our premises to prove a process and weld capability should this be required prior to batch welding.

And, any batch size can be economically welded on our systems, providing customers with high quality welded parts at cost-effective prices whatever the quantity.

Powder Coating

The Pentangle Fabrication powder coating system consists of a state-of-the-art Primasprint Airfluid XE applicator system. This manual applicator is designed to draw powder directly from the manufacturer’s original box and is perfect for small batches or where frequent colour changes are required.

Prior to application of the paint powder, the items are washed in two stages using our RDM ‘AQUAEX TM’ water wash spray booth. The components are then baked in the RDM ‘Modulair’ forced fan air recirculation type box oven, controlled by the RDM LOGIKoC programmable logic control system.

The result of this investment into the latest technology is perfect powder coating whether for a small batch or larger scale production.

CNC Pressing

We have invested in the best to offer enhanced CNC pressing to our customers.

Our Bystronic Xact CNC Pressbrake 160/310 press includes dynamic crowning, giving equal bend accuracy across the entire width of the machine. Complicated bend sequences can be proven out on screen prior to any material being processed.

Rated at 160 tonnes over a 3.1m length, the Pentangle Fabrications’ Bystronic Xact CNC press provides ample capacity and quick set up cycles. The result is quick turnaround at minimal cost, whether it’s a one-off sample or regular batch work for just-in-time production.

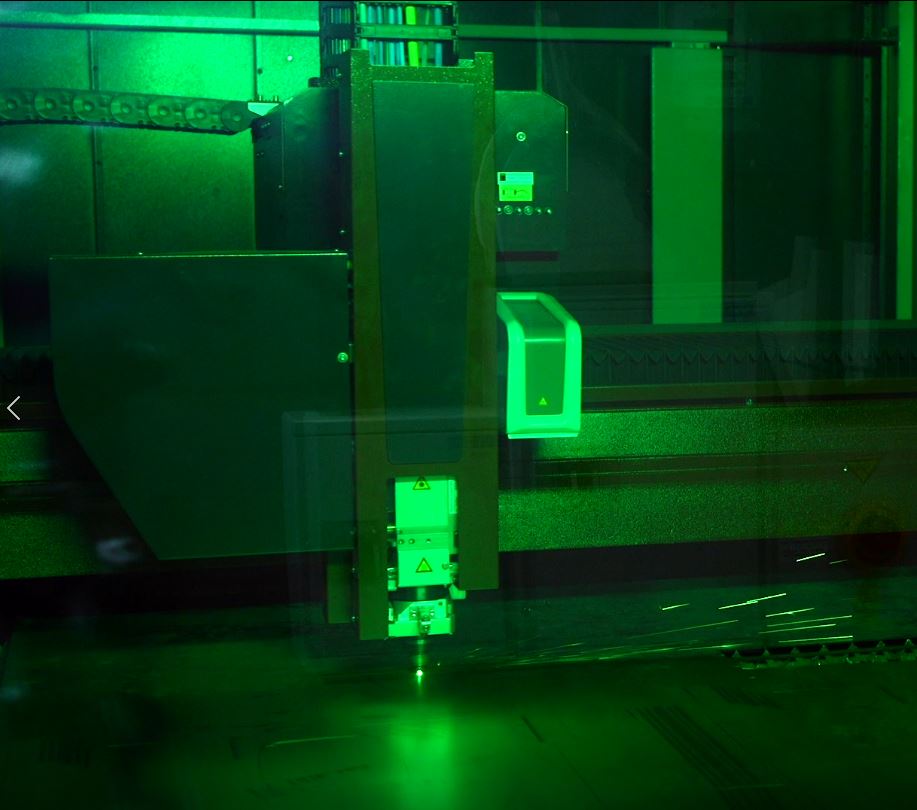

Laser Cutting

Laser cutting has become one of the world’s most common processes for producing parts of almost limitless complexity from sheet materials, with accuracy of +/- 0.15mm. No tooling cost laser cutting is now the industry norm.

We have invested in the state-of-the-art laser technology at our Grantham facility, installing a Bystronic BySmart Fiber 3015 laser processing system. The high-speed cutting offered by Bystronic is in a class of its own, with 4.4 kilowatts of laser power. The system provides outstanding cutting performance and excellent cutting quality for a variety of metals – from steel to stainless steel and aluminium. Non-ferrous metals can also be processed with excellent quality.

We cut parts direct from customer drawings using the latest high performance Bystronic BySmart software. So, if it’s one piece or a regular order you need, produced to exacting standards at reasonable part costs, contact us.